Atom Solar-Tracker

Build & install a manually adjustable marine solar panel mount

We think of it as transom jewelry! 🙂

The typical locations and fixed mounting methods for installing solar panels on a sailboat means they seldom work efficiently because they are not pointed at the sun or are shaded by the rig. For ease of installation and cost, most panels are mounted flat and have no ability to be adjusted to point to the sun for maximum output. Since their output is reduced, a large solar array is needed to keep up with all the electrical loads on a modern cruising sailboat. This is particularly inefficient on a small boat with more limited space. For over 20 years I have used my own design of a fully adjustable pole mounted solar panel tracker on my boat and have built and installed many for other sailors.

The best location for a solar panel on a sailboat is high up and aft of the boom where shading is least. A pole mount accomplishes this like no other solution can. But there is a limit to how much solar a small boat can add to a pole mount. For this reason it is best to economize as much as possible on your energy consumption to match what you can easily generate. If two 50-watt panels on pole mounts is not enough for your needs then they can be supplemented with less efficient flexible panels added on top of a bimini or dodger or on the seahood forward of the dodger.

I currently only manufacture the Solar-Tracker for local customers whose boats I’m refitting. The cost is $750 each. If you want one or two Solar-Trackers for your boat, I’ve provided instructions and sketches below that you can either give to a local metal fabricating shop to build for you or try DIY if you have the tools and skills to cut, drill, weld and polish stainless steel. Another alternative is to buy a similar version pole mount from Custom Marine Products. Theirs is a larger aluminum version that works slightly differently but is well-suited to larger boats and can handle 100-watt panels, where my Solar-Tracker is best suited to 50-watts each, although 80-watts is doable if you have the space.

The Solar-Tracker is operated by simply tilting the panel towards the sun a few times a day when extra power is wanted. Otherwise, just leave it horizontal and forget it.

![]()

On smaller boats with less power requirements a single Solar-Tracker may be sufficient.

Solar-Tracker Fabrication Instructions

Version 2021

Parts:

316 Stainless Steel Materials: (it’s possible to buy online but probably best to purchase steel from a local supplier)

1. One piece polished stainless tubing 1 1/4” x 40 to 48” long x .065 wall.

2. One piece polished stainless tubing 1 1/2” x 3 7/8” x .120 wall. (to fit over main tube for swivel)

3. One piece stainless steel flat bar 3/16” x 2” x 10 ½”. (bend for swivel U-bracket)

4. Two pieces stainless steel flat bar 3/16” x 2” x 2 ½”. (weld to angle bars)

5. Two pieces stainless steel angle 1/8” x ¾” x ¾” (length to fit solar panel frame width).

6. One piece stainless steel flat bar 1/8” x 2” x 6 ½”. (bend for base mount)

Other parts:

1. One 50-watt solar panel – the standard Solar-Tracker kit in 2021 is sized to fit the Renogy RNG-50D-SS, which is 19 5/8” wide on its narrow side where the Solar-Tracker brackets install. (The same model sold in Canada in 2021 was slightly wider at 20.0” so best to order your panel first and confirm the size before cutting steel.) If using another panel in the 50-80-watt range, you’ll need different length brackets.

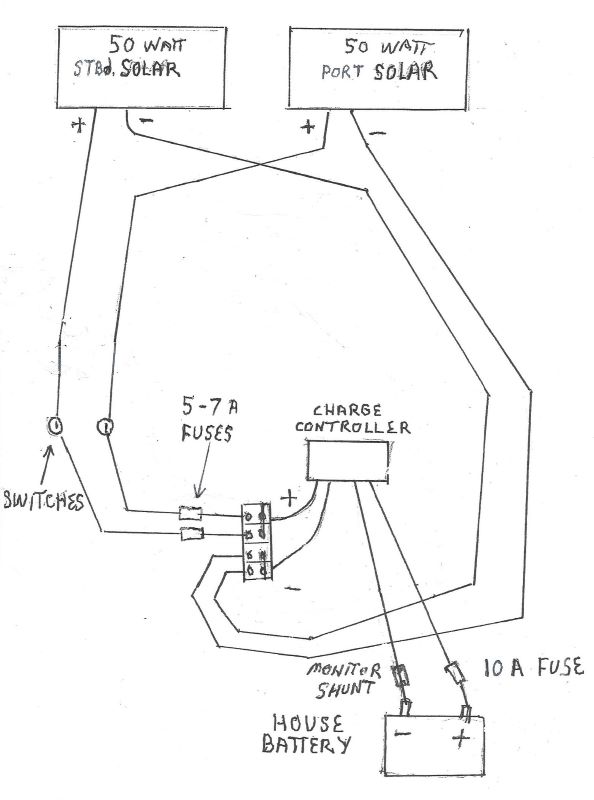

2. 12AWG marine tinned duplex wire, two sets male and female spade connectors, solar charge controller, on/off switch, a 5-7-amp and a 10-amp fuse and holders, and a 4-gang terminal block if installing two Solar-Trackers to one charge controller. (See wiring sketch below).

3. Four pieces furniture corner cushions or solar corner protectors MKS10200 (emarinesystems.com).

4. One piece plastic threaded stud knob – 5/16”X 1” long stud, washer and nut (mcmaster.com #5993k95).

5. Four sets ¼” x ¾” hex head stainless steel bolts, nylok nuts, stainless washers and eight pieces nylon washers.

6. One set 5/16” x 2” hex head stainless steel bolt and nylok nut.

7. Two sets 3/8” x 1 ¼” hex head stainless steel bolts, nylok nuts, stainless washers and nylon washers.

8. Two sets ¼” stainless hex head bolts, washers and nylok nuts to mount base to deck. Most boats require bolts about 1 1/2” long.

9. One piece stainless 7×7 flexible wire 1/16” x 10” and two West Marine Seafit #2684157 zinc-plated copper sleeves.

10. One piece 1” to 1 ¼” stern rail clamp (Garhauer.com).

11. Tube of 3m Black Super Weatherstrip Adhesive.

12. Optional: Blue Seas Side Entry Cableclam, if not using wiring hole in base.

Fabricating instructions:

Note: Before fitting Solar-Tracker to boat, check clearance to boom, dinghy davits, windvane or other gear using a carboard pattern of solar panel dimensions on a boat hook or broom handle. You can also experiment with different heights up to 48”. I’ve found that 42-48” is ideal for most boats and is a good compromise between keeping them low enough to reduce windage, be strong enough to resist damage from the boats motion in high waves and wind and be less unsightly, while being high enough to be unshaded and provide reasonable clearance underneath.

1. Cut steel to length.

2. Machine polish flat bars and angle bars to remove mill finish to have less surface corrosion and make it possible to hand polish them later as needed. It’s easier to machine polish now rather than after bending and welding but you will still need to touch up the polish after welding to remove welding marks.

3. Using a TIG machine, weld 2” x 2 ½” flat bars to angle bars, then round corners slightly. (Whenever possible, use autogenous fusion welding technique (no filler rod added) to reduce warping from excess heat and shrinkage.

4. Bend base bracket and U-shaped swivel bracket and round corners slightly. If you can’t bend perfectly accurate then cut and weld for 90-degree angles on a jig. If they are not accurate then the tilting can jam and not work well.

5. Drill all holes.

6. Tack weld 5/16” nut centered over the 3/8” hole in 1 1/2” tube. Here you need filler rod on the weld for better strength than just an autogenous weld. Take care not to deform nut with too much heat. Run a tap through to clean the threads after welding.

7. Weld 1 ½” tube to bottom of U-shaped swivel bracket. Make sure welded nut is located under the overhanging bracket as in sketch so that tension knob does not strike bottom of solar panel when tilted vertically.

8. Polish welds.

9. Assemble angle bars using a nylon washer between angle bars and swivel bracket. Use your judgment to tension it so that panel can be pivoted but won’t be too loose to hold its position. Apply Loctite under the lock nut and allow to harden.

10. Dry-fit the assembled upper end of the Solar-Tracker by laying angle bars across the center of narrow side of solar panel frame and mark location of four holes. Always protect the solar panel when drilling frame by placing a small scrap of plywood under the solar panel flange. Drill 1/4” holes. The Solar-Tracker angle bars have the mounting holes centered 5/8” inboard from the outside edge of the solar panel. If the holes are any closer to the edge there will not be enough clearance for the washers and nut. Remove solar panel and set aside.

11. Place 1/16” wire through hole in 1.25” tube and crimp a copper sleeve to inside end. Then crimp an eye in outer end.

Solar-Tracker Installation and Operating Instructions

Version 2021

Installation:

1. Attach rubber corner protectors to bottom corners of solar panel with 3m Black Super Weatherstrip Adhesive. It works like a contact cement – apply to both surfaces and let tack up before pressing together. If you use a lesser quality adhesive, the protectors may fall off. Always use corner protectors to avoid injuring someone who is sitting or working under the solar panel and gets up without looking up.

2. Dry-fit the assembled upper end of the Solar-Tracker by laying angle bars across the center of narrow side of solar panel frame and mark location of four holes. Always protect the solar panel when drilling frame by placing a small scrap of plywood under the solar panel flange. Drill four 1/4” holes. The Solar-Tracker angle bars have the mounting holes centered 5/8” inboard from the outside edge of the solar panel. If the holes are any closer to the edge there will not be enough clearance for the washers and nut. Remove solar panel and set aside.

3. Fit 1 ¼” tube with base bracket attached to pushpit rail using the included rail mount bracket. Reposition as needed to select a location to mount the base either horizontally on deck or vertically against a coaming so that tube will be vertical in both directions. (It is acceptable to have the top of pole angled back slightly in the fore and aft plane as long as you keep it vertical athwartships. Place a piece of cardboard of the same size as the solar panel over top of tube if you need to confirm location does not interfere with objects on boat such as windvane self-steering. If the pushpit does not line up with the preferred base location then you may need to use a custom stand-off bracket as in the photo below. Using the base as a guide, drill ¼” bolt holes and a 7/16” wire hole in deck and install with sealant. To ensure alignment is correct, before tightening, attach 1 ¼” tube to base and pivot the base until it lays flat. If the fiberglass in that location has a balsa core then drill the holes at least 1/8” larger, inject thickened epoxy and redrill to correct size.

4. Assuming you want the solar panels easily removable for long-term storage or if stripping the boat of windage for a hurricane then you cannot use the MC4 connectors supplied with the solar panel because the connectors are too wide to fit through the swivel assembly. Instead, run the 12AWG marine tinned duplex wiring from location of solar charge controller through the deck and Solar-Tracker base, up the tube and extending out the top about 12”. Add sealant above and below where wire penetrates deck. Cut one wire 1” shorter than the other and add two spade crimp connectors. The offset connectors will be easier to later feed through the 5/8” hole on top of swivel bracket. (As per the wiring sketch below, wire the solar charge controller, on/off switch, fuse and holder, and a 4-gang terminal block if installing two Solar-Trackers to one charge controller. If for some reason you cannot run the electric wire through the base bracket then run it out the bottom of tube and install a Blue Seas Side Entry Cableclam in a nearby location.

(If you prefer to use the MC4 connectors you can still remove the panels by unbolting them from the swivel assembly, which is doable but less convenient. In this case, buy a matching set of MC4 connectors on Amazon that have at least 6-foot cables attached and run them through the deck and splice your #14 duplex to the ends so that the wire reaches the solar charge controller.)

5. With solar panel placed face down on a table, bolt on the Solar-Tracker swivel – insert bolts from the bottom of stainless angle, place a nylon washer between stainless angle and solar panel, then another nylon washer above panel flange and add a stainless washer and nylok nut. This prevents corrosion by not allowing any stainless parts to be in contact with the aluminum panel frame.

6. Pass the wire through the 5/8” hole as you lower the solar panel assembly down on the tube. It can be done alone but is easier if someone assists you. Connect the eye of the 1/16” wire under the tension knob then add a washer and nut to retain it so the knob cannot vibrate loose and fall off. Do not fully tighten the because it needs to be loose enough that the knob can still rotate around the wire eye. Secure the nut with high strength Loctite. The wire serves to prevent the panel from being swiveled more than one turn in any one direction and straining the electrical wires and as a theft deterrent and to prevent accidental loss overboard.

7. Taking care to observe correct polarity, connect the wire spade connectors to corresponding connectors on wires coming out of solar panel plus a few inches extra slack. Before connecting, apply a silicone electrical contact coating to spade connectors and then wrap with waterproof rigging tape. Take care not to short out the wires when working on them if the solar panel is uncovered in the sun.

To avoid damaging the solar charge controller, always connect it to the battery first and then to the solar panel. Many of the cheaper MPPT controllers out there are not true MPPT technology so beware and read the user reviews when making a selection.

8. Check that the tension on the two 3/8″ bolts on the swivel bracket is sufficient to keep the panel in place but not so tight that it’s difficult to adjust the panel without overstressing its aluminum frame. Use your own judgment here. To add tension, loosen all nuts, add medium or high strength Loctite and retighten. Wait until Loctite hardens before moving panel.

If a stand-off bracket is required you may be able to order one from Garhauer.com or take the standard bracket, grind off the weld and weld a tube of the correct length onto it.

Operation:

When extra output is not needed, leave the panels in horizontal position. When extra output is required, rotate the panels every couple of hours to track the sun or after making significant course changes. Resist installing anything above the panels such as antennas or a wind generator because any shading drastically reduces output.

To prevent damage, it’s best to turn the panels vertical when entering or departing a marina slip to avoid contact with another boat’s rigging or dock pilings.

If the 3/8” bolts become too loose over time to hold the panel tilted in rough seas and strong winds, retighten the bolts and use Loctite on the threads as described in #8 above.

The panels normally won’t interfere with wind flow to windvane self-steering because the wind just flows around them but in certain cases when wind is well forward of the beam and the sun is at a low angle with panel tilted nearly vertical, you may need to tilt the panel closer to horizontal.

50-watt panels are small enough that they can be left in place in storm force winds but for hurricanes or if using larger 80-watt panels, they should be stored below when conditions warrant by disconnecting the spade terminals on the wires, removing the retaining wire under the tension knob and lifting panel with upper assembly off the main tube. Or at least add some rope lashings to better secure them.